Description

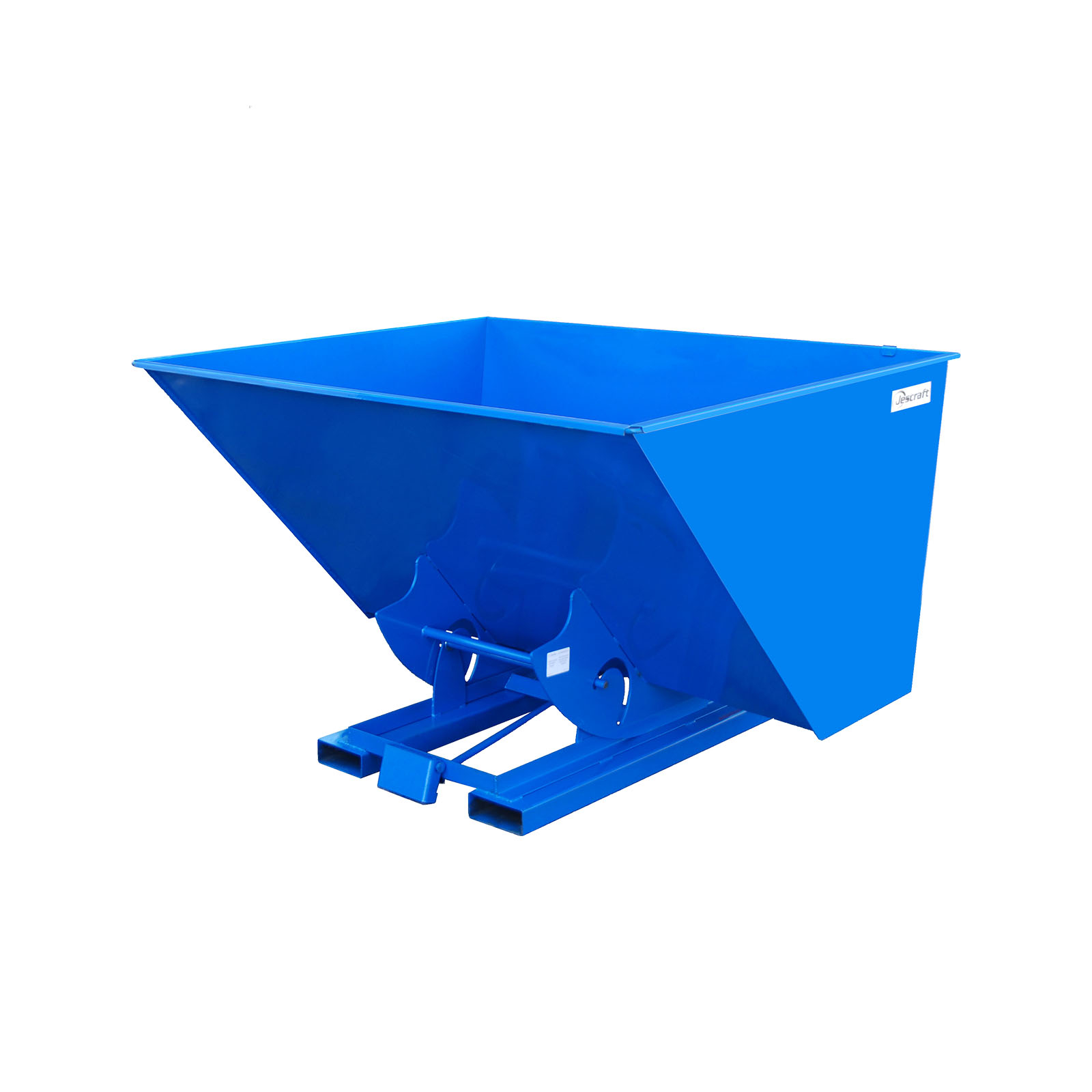

The Self Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more. Constructed of heavy duty steel, this all-welded forklift hopper is built for lasting strength and durability. It can temporarily store just about anything, from garbage to bulk material, and can be transported or dumped easily.

All self dumping hopper units include a safety chain to secure the hopper to the forklift for safe and effective transportation. In addition to the safety chain, a Hopper Safety Lock (sold separately) prevents the hopper from unintentionally dumping caused by travelling over uneven ground…a smart option for rough terrain jobsites.

The forklift pockets interior dimensions are 8″W x 3″H. The fork pocket center is 28.875″, suitable for forks of standard forklifts, telehandlers and skid steers.

How does a Self Dumping Forklift Hopper work?

The self dumping forklift hopper works by releasing a latch mechanism. The latch is spring loaded and secures the hopper in the upright position for filling. After the hopper is loaded, the load can be dumped from the seat of a forklift. Also know as “bump and dump”, the bumper release is activated when the bumper pad hits or bumps into the receiving container, releasing the latch and triggering the dumping action. The forklift operator can also use the manual release cable to to tip the hopper. To achieve this, the operator pulls the 50″ extended release cable, which releases the latch, triggering the dumping action. Once the latch is released, the hopper rolls forward to empty debris. After the hopper is emptied, it automatically rocks back to upright and locked position.

Caster Options for Forklift Hopper

Choose from popular caster options to to increase the dump hopper’s versatility and functionality. You can maneuver the hopper in places a forklift may not fit and transport materials over ground surfaces by adding casters. The most requested caster options are Phenolic or Mold-on Rubber casters; however, additional caster/wheel options can be requested (including Elastomer and Pneumatic). Each caster/wheel set contains 2 rigid front casters and 2 swivel rear casters. The swivel casters are mounted on a kingpin swivel rig, featuring a stamped double row ball bearing. Each caster rig is easily secured with 4 bolts and 4 nuts directly to the base of the unit. This makes changing a caster on the jobsite quick. Easy on, easy off!

Standard caster options:

- 8″ Mold-0n Rubber Caster: Heavy duty caster, made of rubber molded onto cast iron rim. The molded rubber features a hardened top plate for longer wear.

- 8″ Phenolic Caster: General purpose, high capacity caster. Made of phenolic resins, this caster resists oil, grease, gasoline and mild acids. It is easy rolling, quiet, and non-marking.

Caster Replacement

It is important to inspect casters frequently for wear and/or damage and replace casters as necessary. Replacing a caster is easy and can be done with very little downtime. Simply unfasten the bolts from the nuts and replace with a new caster rig. The unit is designed with a 3″ x 3″ bolt pattern and replacement caster rigs can be purchased here.

CAUTION: The self dumping forklift hopper must be attached to forklift when dumping. OSHA requires contacting the manufacturer of your forklift to request specifications for the use of any forklift attachments to ensure your equipment has the adequate capacity to handle the desired load. Refer to your forklift operator manuals for more information.

Product images shown are for illustration purposes only and may vary from actual product.

*Note: Always distribute load evenly. When uniform weight capacity is calculated for any product, the capacity is based on the weight being uniformly distributed over the entire usable area. For those products with casters or wheels, the maximum weight capacity is the lowest weight capacity of either the product or the set of casters/wheels.