- Forward-tilting hopper

- Bumper release or cable release with 50" extended release cable

- Useable forklift pockets (8"W x 3"H)

- Safety retaining chain

- Choose various caster types

- Optional locking caster brake sold separately (Model #ACC-166)

- 2,000 lb. capacity

Jescraft manufactures a variety of forklift and mobile hoppers for material handling, each fabricated with heavy duty steel to withstand rugged jobsite or in-plant handling. Nearly all our hoppers feature casters for easy mobility on plant floors or tight spaces otherwise inaccessible by forklifts. Our caster options suit a particular environment, from non-marking to cushioning, ensuring in process materials are safe and kept “on the move”. Also, many of our hoppers have specialized uses, such as self-dumping or chip collection, and therefore designed with specific features. These versatile options ensure customers have the right equipment for the job, making work efficient, safe and cost effective.

-

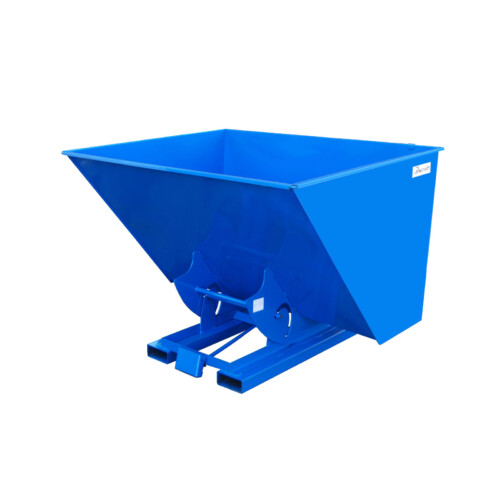

The DH Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.

The DH Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more. -

The Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.

The Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.- 10 gauge steel hopper

- Forward-tilting hopper

- Bumper release or cable release with 50" extended release cable

- Useable forklift pockets (8"W x 3"H)

- Safety retaining chain

- Choose various caster types

- Optional locking caster brake sold separately (Model #ACC-166)

-

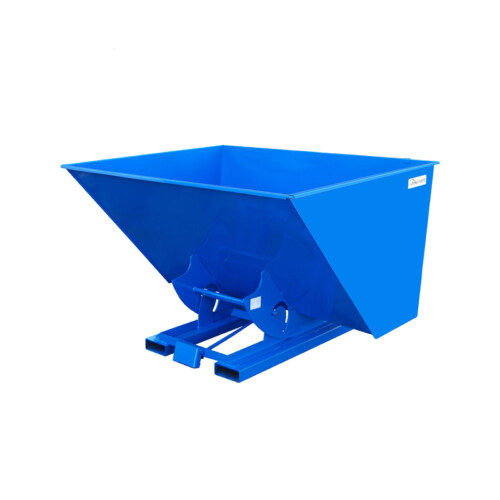

The DH Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.

The DH Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.- 10 gauge steel hopper

- Forward-tilting hopper

- Bumper release or cable release with 50" extended release cable

- Useable forklift pockets (8"W x 3"H)

- Safety retaining chain

- Choose various caster types

- Optional locking caster brake sold separately (Model #ACC-166)

-

The Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.

The Self-Dumping Forklift Hopper is designed for various material handling jobs including construction, waste management, sanitation and more.- 10 gauge steel hopper

- Forward-tilting hopper

- Bumper release or cable release with 50" extended release cable

- Useable forklift pockets (8"W x 3"H)

- Safety retaining chain

- Choose various caster types

- Optional locking caster brake sold separately (Model #ACC-166)

-

The Self-Dumping Mobile Hopper makes handling commercial or industrial waste easy and efficient. This hopper features casters for easy mobility and its lower profile is ideal for general facility maintenance, wood or metal scrap collection, construction debris, or recycling material.

The Self-Dumping Mobile Hopper makes handling commercial or industrial waste easy and efficient. This hopper features casters for easy mobility and its lower profile is ideal for general facility maintenance, wood or metal scrap collection, construction debris, or recycling material.- Constructed of steel

- Easily dump load while seated on forklift

- Latch secures hopper in upright position during transport

- Convenient push handle for easy mobility

- Safety retaining chain

- Useable forklift pockets (7" W x 2"H) on 24" centers

- Choose from 2 caster types

- Optional locking caster brake sold separately (Model #ACC-166)

-

Low Profile Chip Dump Cart

The Low Profile Chip Dump Cart, also known as a manual tilt hopper, is designed to collect loose or scrap materials, such as parts, metal shavings, or wood chips for manual dumping. The chip cart dimensions are designed to fit under conveyors or production machinery.- 8.6 CU FT

- 14 gauge steel construction

- Features a 1.25" diameter handle

- 8" High-performance Elastomer Casters, 2 Rigid/1 Swivel

- Minimum Cart Lip height: 25.85”

- Click here to view Operational Safety and Assembly Instructions